Cyndi Rhoades is the CEO of UK-based Worn Again and she believes that the inherently unsustainable fast fashion industry can be sustainable, and more importantly, circular. She’s all set to prove it too, with a Swiss-based recycling plant set to open next year which will provide the test case for investment in global apparel recycling “at a molecular level.”

“However, the vision of the future of textiles plays out, it should go beyond organizational and territorial barriers. Solving the waste crisis will work far better if the industry’s biggest brands work together rather than against each other. What we need is a global consortium spearheading transformation.”

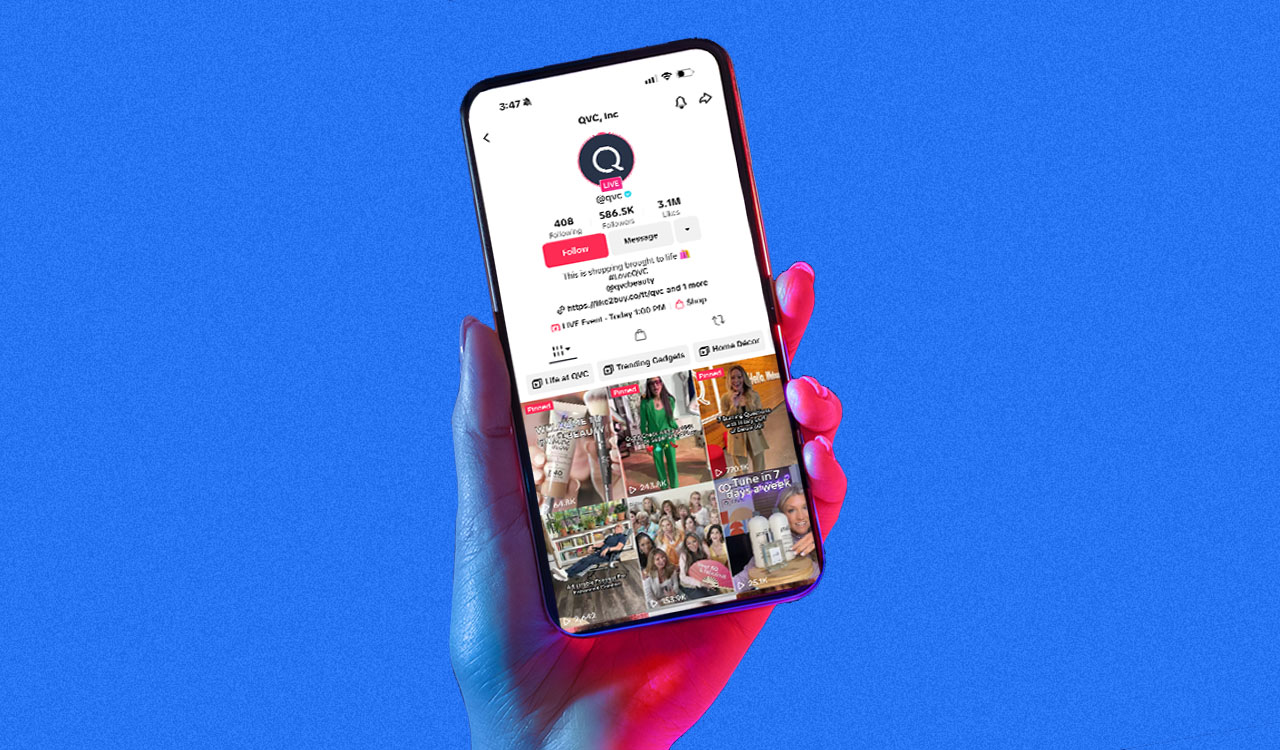

So what’s the plan? Well let’s look at the situation first, where the onus to be sustainable is really picking up pace, despite a conflicted consumer. Right now, the major fashion brands are speaking sustainability to an audience of consumers who often argue vehemently for their fashion options to be greener and more ethical — and then go onto social media to show off cheap chic fashion hauls. Yes, the age-old question continues: Green sells, but who’s buying?

Apparel Recycling: A One Percent Industry

Globally only about a third of unwanted apparel is collected, according to consultancy McKinsey & Co., and of those less than one percent is recycled into new clothes, according to the UK non-profit Ellen MacArthur Foundation.

But the global fashion brands — arguably responsible for much of the fashion waste and unsustainable manufacturing processes — are starting to get serious about how they fit into the circular economy and in particular how meaningful initiatives can be executed at scale.

Earlier this year, the circular dilemma led Japanese fashion retailer Uniqlo, part of the Fast Retailing group, to host a two-part road trip to New York and London to discuss how it is extending its repair and reuse service within some of its larger stores.

Who could argue about such a genuinely commendable project that encourages customers to bring old products back into the store to be repaired or, if that moment has passed, to be recycled? That said, the impressive Tokyo-based management freely admitted that taking this concept from a bespoke to a mainstream offer was going to be tough; it’s a nut yet to crack.

Second Life

In the U.S., clothing staple Gap recently moved in on a growing trend for second-hand apparel with Gap Vintage. Working with Gap, superfan Sean Wotherspoon – an American vintage collector, retailer, and a founder of the NFT digital fashion brand MNTGE – has created a limited assortment drop. Gap picked up on the opportunity after resale platform Depop and marketplace eBay reported strong vintage Gap sales.

Denim retailers have also explored the vintage channel, including Levi with Levi’s SecondHand which launched in 2020 with a buyback program operated by Trove. Denim brands Lee and Wrangler have also released small vintage drops, using merchandise sourced by their teams.

U.S. outdoor fashion and sports retailer Northface is to launch its reuse service for Europe in the UK first. Emily Bolon, CEO of Looper Textile, which works with H&M among others, is a strong advocate of reuse strategies, stressing that all garments have value, even outside their primary channel. Demand for recycled fiber is growing, she says, but 60 percent of unwanted garments in Europe are thrown away, which escalates to 82 percent in the U.S. Think about that for a moment.

Mitigating the Waste Stream

Looper has handled over 40 million garments so far. In a tie-up with H&M announced last February, Looper will collect used and unwanted apparel from municipal containers across Europe, alongside H&M’s own in-store collection program, which it put in place back in 2013. The company reckons that up to 60 percent of items will be suitable for resale, distributed via a network of companies online, across off-price second-hand chains in Eastern Europe and through importers in Africa.

Around one-third of apparel will go to recycling plants to be downcycled, predominantly into auto insulation or sofa stuffing, while the remaining approximately five percent of garments unfit for reuse or recycling will be incinerated for power.

Engineering a Breakthrough

But Rhoades believes her business can go one better. She says that recognition of the problem has failed to turn into tangible improvements because the solutions aren\’t there yet. She also separates the concepts of sustainability and circularity. “Sustainability is about doing things a little bit better; circularity is about systems change,” she says.

“Lack of progress is what has engendered cynicism,” she states, but she believes that we are at the dawn of a new era of how textiles are going to be made, going to be used, and going to be recirculated over the next five decades.

Worn Again evolved from an ambition to deal with (read eradicate) the problem of textile waste. The first iteration of the company looked at upcycling, but Rhoades concluded that was a quick fix, not a solution. In 2012 the company hit on a recycling technology not at the textile level, but at the molecular level with the development of a chemical recycling technology that could deal with both polyester and poly-cotton blends.

When synthetic textiles are treated, the end-product material can replace polyesters or, for cotton, produce a pulp that can be spun back into fiber. The company is building a demonstration plant in Zurich, scheduled to be up and running next year. The facility will then act as the blueprint for an industrial-scale plant that Worn Again will license to plant operators around the world.

Scaling Up Is Key to Transformation

The goal is to replace as much virgin polyester and cellulose production as possible, with each plant capable of processing around 50,000 tons per year (against the 60 million tons of polyester waste being produced annually). This is a significant paradigm shift. There is enough recyclable/re-processable fiber to stop producing it in the first place. Rhoades believes that scaling up will prove to brands, retailers, and consumers that this technology works.

Her plan dovetails with the Circular Textiles Strategy: The European Union is upping the ante on circularity regulations, with a requirement to collect discarded, unwanted textiles separately by 2025.

As for collection, that’s going to need a new approach. In the UK, grocery chain Asda has launched a program for its food delivery trucks to collect shoppers’ unwanted textiles, which are returned to the chain’s distribution centers. Rhoades says it\’s that sort of thinking that reflects innovation in collection.

She has also set a company up called Circle Eight, which is researching how best to tackle sorting textiles into different fiber compositions through automation. And she emphasizes that she has never been more hopeful of the progress that is happening than now. “Maybe I\’m just an optimist,” she reflects. We can attest you have to be an optimist to transform the world’s textile supply chain.

Circling Back on Circularity

Spoiler alert: I’m not a chemistry graduate. So, the efficacy of the complex technology running the Worn Again plants is a topic for experts and scientists. But what it clearly represents to the layperson is an attempt to bridge that gap between good intentions and reuse at scale.

There’s no doubt that the major European brands have become serious about making their apparel processes more sustainable with the carrot of reuse matched by the stick of regulation. Clearly, both are going to be needed to change behavior.

Being proactive about the planet is big business. There are many companies at various stages of development in the circularity sector. The feedstock specifications, processes and outputs may vary, but the commonality is that they all focus on breaking down non-re-wearable textiles and recapturing and restoring these materials back into the equivalent of high-quality textiles that can be used to replace virgin materials. These pioneers include Renewcell, Infinited Fiber, Circ, Sodra, Lenzing, HKRITA and Ambercycle. This is serious stuff. We may reach the day when virgin textiles no longer need to be manufactured and natural fibers no longer need to be grown.

However, this vision of the future of textiles plays out, it should go beyond organizational and territorial barriers. Solving the waste crisis will work far better if the industry’s biggest brands work together rather than against each other.What we need is a global consortium spearheading transformation. As Looper’s Bolon says, “Closing the loop should not be a closed loop exercise.”