July marked Plastic Free July, a global movement initiated by the Plastic Free Foundation that encourages businesses and everyday people to work toward “a world free of plastic waste.” Using the slogan “Small steps, big difference,” the campaign looks to end plastic pollution worldwide. Those in the apparel industry can help with this initiative by reducing microplastic pollution that stems from synthetic fabrics and switching to natural fibers.

Although Plastic Free July is coming to a close, brands and retailers should consider that, nearly two-fifths of consumers (37 percent) say sustainability or environmental friendliness is important to them when they’re looking at what brands to buy, according to 2022 Monitor™ research. Finally, more than three-quarters of all consumers (81 percent) say better quality garments are made from all-natural fibers such as cotton, according to 2024 Monitor™ data.

Textile Microplastics

While microplastics are a tremendous environmental problem, not everyone knows that textile microplastics are derived from petroleum-based fabrics like polyester, nylon, and acrylic. The CFDA (Council of Fashion Designers of America) cites a report that found 342 million barrels of oil are used every year to produce plastic-based fibers for textiles like polyester. And the Changing Markets Foundation states nearly 70 percent of all materials used in fashion textiles are synthetic fibers. EarthDay.org asserts 35 percent of all microplastics in the ocean come from washing synthetic clothing – as the tiny microfibers come out in the laundry effluent and enter our waterways. Fashion Revolution found up to 700,000 microplastic particles can come off synthetic apparel in a single wash.

The microplastic pollution problem isn’t limited to water. The Plastic Soup Foundation found these particles can be found in the air and land, too, thus entering the food chain. A study by the non-profit delved into the health issues caused by the ingestion of microplastics. And scholarly articles have found microplastic pollution is also contributing to climate change. Not only do the plastic microfibers contribute to greenhouse gases, but they can take hundreds of years to decompose.

Reversing the Surge

While all of that sounds grim, the fashion industry isn’t powerless to bring forth change. Something as simple as switching to natural fibers like cotton can help brands combat the microplastic pollution problem, starting at the ground level.

“All clothing sheds little pieces of fiber but what’s important about cotton is it biodegrades in a relatively quick time,” says Cotton Incorporated’s Dr. Jesse Daystar, vice president and chief sustainability officer. “Meanwhile, synthetic fibers take hundreds if not thousands of years to decompose. Biodegradability of apparel is crucial for reducing waste, conserving resources and minimizing environmental impact. Cotton can decompose under the right conditions and doesn’t contribute to microplastic pollution.”

This ability to decompose matters to consumers, as 76 percent say it is important that clothing be made from materials that can biodegrade, according to Cotton Incorporated’s 2022 Apparel Sustainability and Back to the Office Study.

Natural Advantage

The reason cotton biodegrades so readily is due to it being a natural, cellulose-based fiber composed of long chain glucose molecules. Living microorganisms like bacteria and fungus consider this a food source. So, whether in soil or wastewater, freshwater, or saltwater conditions, cotton microfibers readily biodegrade while synthetic microfibers like polyester do not. This is something brands might keep in mind, especially during Plastic Free July.

Andine, which has a shop online and in its home city of Los Angeles, and whose products are stocked in stores such as Neiman Marcus, Saks Fifth Avenue, and Fred Segal, has already gone the natural route, making fibers like cotton a first choice, according to founder and designer Elisabeth Weinstock.

“Andine strives for quality goods made from natural fibers,” Weinstock told the Lifestyle Monitor™ in an interview. “We prefer to use fabrics that are as soft as butter and made 100 percent out of cotton. As a loungewear brand, we encourage our customers to wear our items all the time, whether they are home or out on the town, so long as they are feeling comfortable and looking chic. We thrive on producing high quality pieces that will last a long time, and natural fibers help us achieve that goal.”

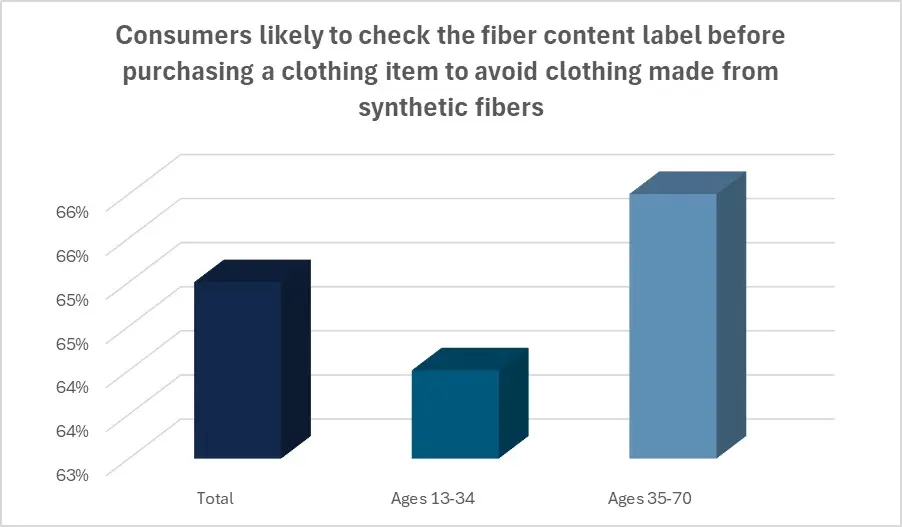

That’s a goal that’s appreciated by consumers. As it stands, the majority of consumers (65 percent) say they are likely to check fiber content labels before purchasing a clothing item to avoid garments that are made from synthetic fibers, according to the Cotton Incorporated 2024 Lifestyle Monitor™ Survey. Further, nearly 3 in 10 shoppers (29 percent) say they’re bothered that brands and retailers are using synthetic fibers in their clothing.

Cotton First

This concern about synthetic fibers comes as 45 percent of all consumers say they’re aware that clothing microfibers are polluting oceans and waterways, according to the Monitor™ research. This awareness has grown significantly over the last six years, from 27 percent in 2018 to nearly half (45 percent) of all consumers today. And of those that are aware, about two-thirds (65 percent) say they know it comes from laundering apparel made of synthetic fibers like polyester.

Designers looking to cut back on synthetics and expand their usage of cotton fabrics can find inspiration through Cotton Incorporated’s FABRICAST™ library, which showcases a series of cotton and cotton-rich fabrics. The collections highlight new and interesting yarns, unique weaving and knitting constructions, dyeing and finishing techniques, as well as fabric performance technologies.

The whole point of the FABRICAST™ library is to give product developers, manufacturers, and retailers the most from cotton. These collections are regularly updated to provide new ideas and inspiration for design and development teams.

Recent FABRICAST™ collections featured fabric groupings that focused on performance as well as sustainability. For instance, cotton and wool options that serve as alternatives to synthetic fleece, lightweight, double-sided technical cotton as well as performance bottoms that offer both comfort stretch and water resistance.

High Tech Performance

Cotton Incorporated’s Yvonne Johnson, senior director of product development, says modern fabric technologies allow cotton to compete with and differentiate itself from other competitive fibers, especially synthetics.

“Petroleum-based polyester, essentially a plastic, doesn’t absorb any moisture just like the plastic wrap you use to cover food items,” Johnson explained to the Lifestyle Monitor™ in an interview. “Because it does not have any absorbent capacity, special finishes are used to give polyester fabrics some wicking properties. Cotton, a supernatural fiber, is breathable and absorbent due to its biological structure. Lightweight cotton knits and wovens are ideal for all types of apparel because of their breathability, softness and versatility. Plus, cotton fabrics wash clean every time and never retain odors.”

“Cotton fabrics can be engineered with permanent ventilating openings for enhanced breathability,” Johnson continued. “Additionally, Cotton Incorporated’s TransDRY® and WICKING WINDOWS™ technologies, are finishes that reduce the amount of moisture a cotton fabric absorbs. The technologies move moisture away from the body to the outside of a garment then rapidly spread the moisture for faster evaporation.”

The finishes Johnson referred to are part of a suite of branded performance technologies that Cotton Incorporated has developed. Cotton Incorporated works with suppliers around the world to implement the technologies to make it easy for brands and retailers to use on their own cotton products.

For instance, the TransDRY® and WICKING WINDOWS™ technologies Johnson mentioned are natural solutions for brands looking to create sustainable activewear. These applications help eliminate the feeling of wet fabric against the body. Instead, sweat is transferred from the skin to the outside of the fabric where it can quickly evaporate.

Breathing Room

The fact that these technologies were made for cotton fabrics is a win with consumers. Note that 58 percent of shoppers say they prefer cotton-rich activewear, according to Monitor™ research. Further, 60 percent of consumers seek out moisture-management features in activewear. Already, 61 percent of shoppers describe cotton activewear as breathable, and 45 percent are willing to purchase cotton activewear that wicks moisture and dries faster.

Some of the other branded technologies that have been developed for cotton include NATURAL STRETCH™, TOUGH COTTON™, and STORM COTTON™ technologies. Again, each of these innovations enhance cotton’s natural properties, turning it into a true performance fiber.

Take STORM COTTON™ technology. It is a durable, water-repellent finish for cotton that offers protection from rain and snow while maintaining the natural comfort of cotton. It can turn something like a simple hoodie or a pair of denim jeans into a performance garment that keeps wearers dry and comfortable, rain or shine. Brands should bear in mind that a little over half of consumers (53 percent) say they are likely to seek out performance features when making clothing purchases, according to 2023 Monitor™ research.

In the case of NATURAL STRETCH™, a mechanical stretch technology gives 100 percent woven cotton fabrics ultra-comfortable flexibility without the use of spandex. And fabrics with NATURAL STRETCH™ technology won’t lose their elasticity, even after tumble-drying or ironing – making the solution ideal for categories like woven shirtings and bottoms, as well as denim.

And TOUGH COTTON™ technology brings increased durability and superior abrasion and wrinkle resistance to cotton clothing for the life of the garment. A proprietary dual-process treatment increases the strength of cotton for long-lasting durability while maintaining the comfort of cotton knits and wovens. The technology is ideal for outerwear, children’s wear, denim, workwear, bottoms, and more. The attributes of TOUGH COTTON™ resonate with consumers The majority of parents feel quality (69 percent) and durability (62 percent) are top attributes they look for when back-to-school shopping for their child(ren), according to Cotton Incorporated’s 2024 Back to School Supplemental Survey.

Plastic Free July

Although Plastic Free July is coming to a close, brands and retailers should also consider that, nearly two-fifths of consumers (37 percent) say sustainability or environmental friendliness is important to them when they’re looking at what brands to buy, according to 2022 Monitor™ research. Finally, more than three-quarters of all consumers (81 percent) say better quality garments are made from all-natural fibers such as cotton, according to 2024 Monitor™ data.

That preference for cotton is reflected in some of Andine’s best-selling products, Weinstock told the Lifestyle Monitor™.

“Derived from plant fibers, cotton is breathable, durable and wonderfully soft to wear,” Weinstock said. “From our structured Essen blouse to a flirty Lulu crop tank, the cotton styles offer our customers versatility. Andine is a timeless brand, and we want our clothes to last a lifetime.”