Sizing and fit are top concerns for consumers shopping apparel. According to Shapeometry, in 2019 the apparel returns related to fit hit $60 billion, half of which were returns of online purchases. About 85 percent of apparel returns were due to fit issues. So, the premise of a digital personal avatar sounds great for shoppers, but the reality is that the supply chain cannot deliver to specific avatar sizes. Instead, brands match a personal avatar size to the closest size in the existing product range. Jason Wang, COO of Alvanon explains, \”Retailers have been investing in technologies that allow for customized personal avatars, where the consumer can create a body model of themselves. Using algorithms, the retailer can then match the statistical body model to the closest fitting size in the product line.\”

[callout]As technologies on the front consumer-facing side have become for more mature and accurate in terms of body size identification and fit recommendations, the supply chain lags behind in delivering these custom size products to individual consumers.[/callout]

The mass-market brands are just starting to get more invested in strategies that better match body form to produce styles that meet the target market. Wang suggests that the consistency for garments to match body form could streamline the supply chain and create better efficiencies which in turn would limit the over-production of goods that lead to products being shipped to discounters or end up in landfills.

Why Virtual Fittings?

The retail community is excited about the many uses of artificial intelligence to help solve the problem of trying on apparel, especially now during the coronavirus pandemic where stores are either closed or have modified fitting room procedures. Virtual try-ons provide shoppers with higher confidence in apparel selection and a better chance of making a purchase. Trying on apparel can increase the chance of purchasing by 40 percent and reduce high return rates normally seen by apparel retailers, which vary by business segment but average between 20-40 percent.

In the current Covid-19 environment, apparel returns present massive logistics headaches for physical stores. Many retailers have set up a 24-48-hour moratorium on putting returns back into inventory or use an expensive cleaning process, all of which results in a slower turnover of merchandise and out-of-stocks leading to shrinking margins.

Clear Expectations

While virtual try-ons can reduce many customer pain points, they also may present a service gap between what the customer expects and what the retailer can actually deliver. Virtual try-on apps are used throughout the industry and some technologies promise 3D body scans to create the \”perfect fit.\” Many shoppers are under the impression that virtual try-ons provide products that match their exact body specifications, but this is not true. The technology actually finds the best size match within the brand\’s existing product assortment.

Furthermore, once customers understand they may be giving up their personal data about their sizes, it may become a privacy issue for some customers who would prefer not to reveal this type of personal information with the digital world. While the apps are great to identify which sizes and styles may fit best for individual consumers, retailers that set the customer expectation about the technology\’s limitations upfront will minimize the service gap. In addition, clear use of data collected by apps should be clarified with the shoppers using the app.

Retail Applications

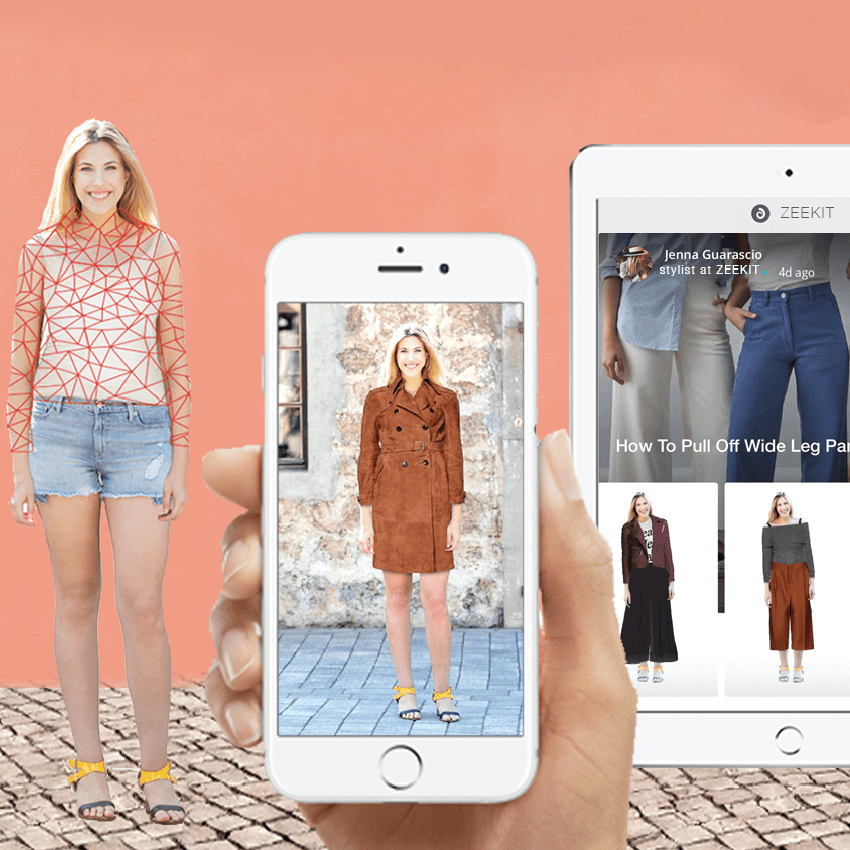

In addition to virtual body scans, AI technologies allow shoppers to use an image of themselves to try on products virtually. Beauty brands, like Sephora and Ulta, have been successful using this type of technology to enhance the customer experience even before the pandemic. Mirrors and apps allow shoppers to try on different shades of make-up on virtual images of themselves. Apparel is more complex with sizing, proportion and design characteristics that impact wearability.

There is also an option for virtual try-on services with minimal software investment using two-dimensional imaging that is relatively easy to integrate into existing platforms. The 2D process uploads product images along with metadata information like garment characteristics, drapability and sizing specifications. A shopper can then upload an image of themselves and try the products on his or her virtual image.

Three-Year Lag in the Supply Chain

Performance wear companies are more advanced than the fashion apparel industry in terms of matching body image to manufactured styles, but these companies heavily invested in this technology prior to Covid-19. Wang adds, \”As technologies on the front consumer-facing side have become for more mature and accurate in terms of body size identification and fit recommendations, the supply chain lags behind in delivering these custom size products to individual consumers.\”

Prior to Covid-19, Wang estimates that the supply chain side of the industry was probably five years away from delivering product sizing to match up with the virtual try-on technologies. However, like many other technologies in today\’s environment, the acceleration of this puts the supply chain behind about three years.

Wang notes, \”The inherent issues with the comparison between the actual body scan to a technical specification is that design tolerances are not taken into account.\” In apparel production, the development process provides certain tolerances to the initial design which may include fabric ease, sewing, shrinking and design intent. This will lead to produced garments not matching the exact actual body size.

Alvanon (full disclosure, Alvanon is a partner of The Robin Report) is a leader in industry innovation and uses cutting-edge technology and body shape data to advise global brands and retailers on the best-fit strategies for its customers promising to reduce apparel returns by 30 percent.

Back to the Future

Virtual try-ons and apps serve a current need in the industry as shoppers continue to be apprehensive about shopping in stores. Online returns, for apparel, continue to challenge retailers. Selling right sized products to shoppers is a cost-effective solution. Some retailers look for ways to improve the processing of returns while others are facing the crux of the problem by focusing on creating better body forms that match a brand\’s target market.

Managing shopper expectations about sizing applications includes full disclosure about technology limitations and privacy information. Transparency about the benefits and potential drawbacks about the technology will make a more successful adoption with shoppers and create deeper loyalty. On the product development side, improving the body forms and minimizing tolerance levels to more accurately portray body measurements of the specific target market will also drive higher levels of customer loyalty.

For sure, retailers and brands should not mislead shoppers into believing virtual apps or 3D scanning technologies deliver custom products — unless they are actually able to produce customized products based on individual sizing dimensions. Custom apparel is where the industry started centuries ago and may be where the industry is headed in the future, but it is not there now.