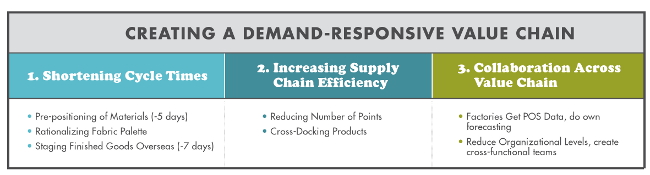

The Omnipresent Retailer: Creating a Demand-Responsive Value Chain

Best Practices from Kurt Salmon Many retailers are striving to better respond to changes in consumer demand, and it’s easy to see why: They’re pressed to reduce inventories and cut supply chain costs at the same time that the shopping […]

The Omnipresent Retailer: Creating a Demand-Responsive Value Chain Read More »